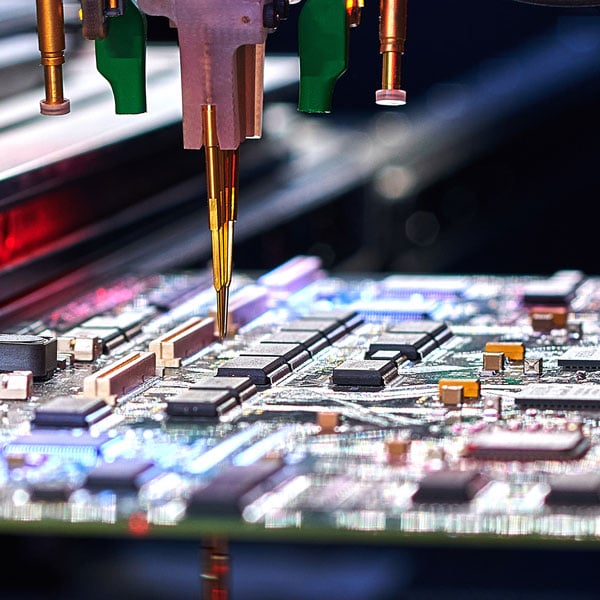

Advanced SMT combined with microelectronics assembly makes ISI a unique manufacturing partner to provide a full, turn-key solution to complex electronic assembly needs.

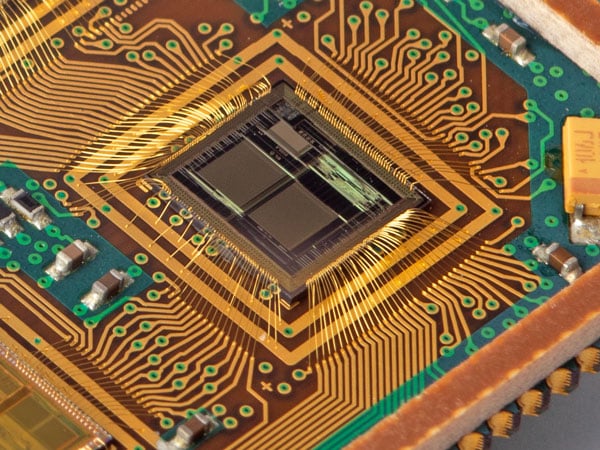

ISI has invested heavily in our bare die assembly equipment and in building a team of skilled bare die assembly and wire bonding technicians. Our extensive bare die handling capabilities allow us to deal with various types of packaging and substrates to deliver complex microelectronics assemblies.

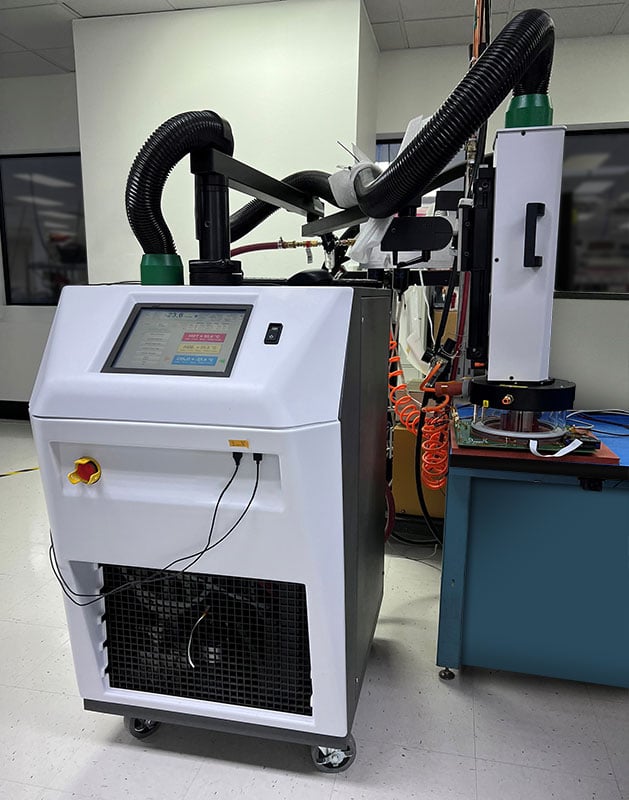

Encapsulation, or electronics overmolding ensures protection against shock, vibration and harsh environments encountered in subsequent manufacturing processes, as well as throughout the lifetime of the product.

ISI’s standard and custom connector products and technologies support a wide range of commercial, industrial and defense applications. Our in-house design and manufacturing capabilities allow us to go from concept to production in weeks.

ISI’s broad testing capabilities ensure product quality & reliability. In addition, ISI can develop and implement a comprehensive test plan to verify performance to customer specifications.

International Traffic in Arms Regulations (ITAR) control the export and import of defense-related articles and services on the United States Munitions List (USML).

The ISO 9000 family of quality management systems standards is designed to help organizations ensure that they meet the needs of customers and other stakeholders while meeting statutory and regulatory requirements related to a product or program.

ISI’s Camarillo facility is an IPC member in good standing and subject to the rules and regulations of the IPC trade association.

"*" indicates required fields